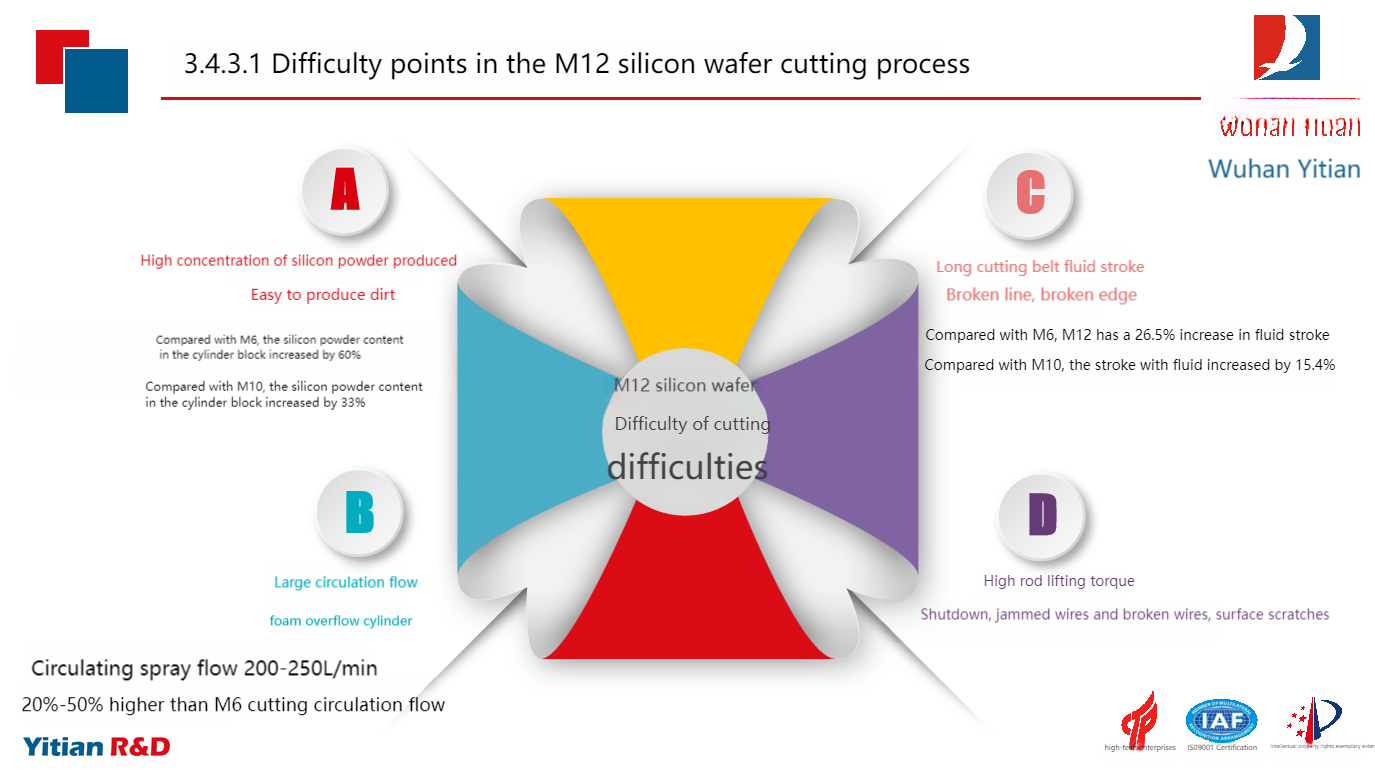

Difficulties in the cutting process of M12 silicon wafers

Release time:

2023-11-20

Summary: High concentration of silicon powder is generated, which is prone to dirt and stains M12 has a 60% increase in silicon powder content in the cylinder body compared to M6 M12 has a 33% increase in silicon powder content compared to M10 in the cylinder block

|

High concentration of silicon powder is generated, which is prone to dirt and stains M12 has a 60% increase in silicon powder content in the cylinder body compared to M6 M12 has a 33% increase in silicon powder content compared to M10 in the cylinder block |

Large circulating flow, foam high overflow cylinder Circulating spray flow rate 200-250L/min 20% -50% higher than M6 cutting circulation flow rate |

The cutting belt has a long liquid travel, with broken wires and broken edges M12 has a 26.5% increase in liquid travel compared to M6 M12 has a 15.4% increase in liquid travel compared to M10 |

High lifting torque Shutdown, wire breakage, surface scratches |